The history of metal fabrication at age steel company

The history of metal fabrication at age steel company

Age Steel Company has a rich history in the field of Metal fabrication & Stainless Steel . Since its inception, the company has been at the forefront of innovative techniques and technologies in this industry. With years of experience, Age Steel has consistently delivered high-quality metal Fabrication solutions to its clients.

The company has a team of highly skilled and dedicated professionals who are well-versed in the intricacies of metal fabrication. From designing and cutting to shaping and welding, Age Steel excels in every aspect of the process.

Their commitment to customer satisfaction and their ability to deliver projects on time has earned them a stellar reputation in the market. As they continue to grow and adapt to new advancements, Age Steel Company will undoubtedly remain a leader in the field of metal fabrication.

what are the 3 main fabrication techniqes

In the world of manufacturing and product development, fabrication techniques play a crucial role. These techniques are used to transform raw materials into finished products, creating objects that we use in our daily lives. In this article, we will explore the three main fabrication techniques that are widely used across industries.

Machining:Machining is a versatile and widely used fabrication technique that involves the removal of material from a workpiece through various cutting tools. This technique is used to create precise and complex parts with tight tolerances.

Welding:Welding is a fabrication technique that involves joining two or more pieces of metal together using heat and pressure. It is widely used in the construction, automotive, and aerospace industries.

Casting:Casting is a Metal fabrication technique that involves pouring a molten material into a mold and allowing it to solidify. This process is used to create complex shapes and is commonly employed in the manufacturing of metal components.

what are the 3 types of metal fabrication

Metal fabrication is a complex and fascinating process that involves transforming metal into various useful products. From large industrial structures to intricate jewelry pieces, Metal fabrication plays a vital role in many industries. While metal fabrication encompasses a wide range of techniques, there are three primary types that are commonly employed. Let's take a closer look at these three types of metal fabrication:

Sheet Metal Fabrication:

Sheet metal fabrication involves the manipulation and shaping of thin metal sheets, usually ranging from 0.006 to 0.25 inches in thickness. This type of fabrication is commonly used in industries such as automotive, aerospace, and HVAC systems. Sheet metal can be easily cut, bent, and welded to create various components and structures.

Structural Metal Fabrication:

Structural metal fabrication deals with the manufacturing of heavy-duty structures and components. It is commonly used in industries such as construction, shipbuilding, and bridge manufacturing. The primary goal of structural metal fabrication is to create strong and durable structures capable of withstanding immense loads and environmental stresses.

Custom Metal Fabrication:

Custom metal fabrication involves the creation of unique metal products tailored to specific client requirements. It addresses a wide range of demands, including one-off designs, prototypes, and specialized components. Custom metal fabrication requires a high level of skill and expertise as it involves working with different metals, welding techniques, and advanced machinery.

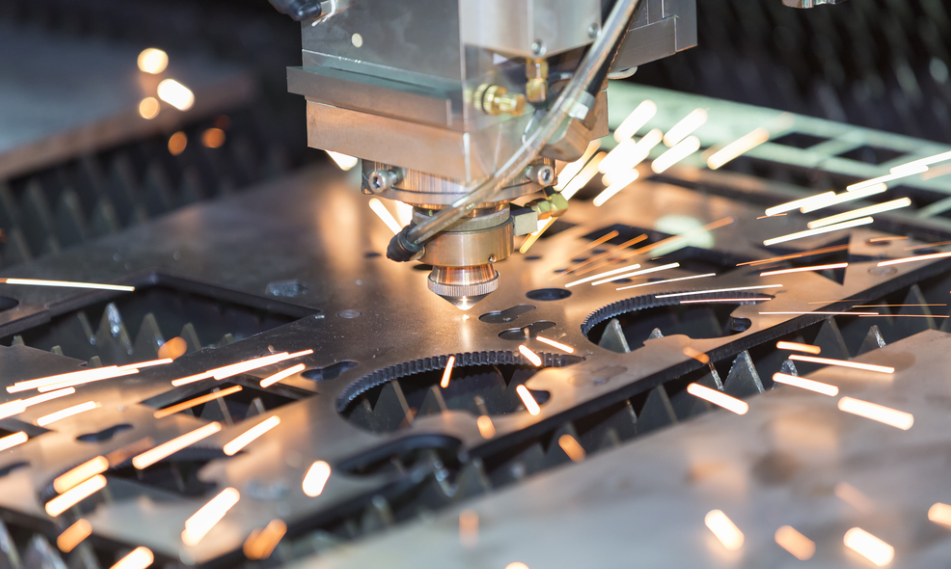

what is a fabrication equipment

Metal fabrication equipment refers to machinery, tools, and devices used in the process of fabricating or manufacturing products. These equipment are specifically designed and engineered to perform various tasks such as cutting, shaping, bending, welding, and assembling materials like metal, wood, plastic, and composites. They play a crucial role in industries such as automotive, aerospace, construction, and manufacturing, where precision and efficiency are key. From CNC machines to laser cutters, press brakes to robotic welders,Steel fabrication equipment enables manufacturers to transform raw materials into finished products with accuracy and consistency.

what are the steps involved in fabrication process

The Metal fabrication process consists of several key steps that are essential in creating a finished product. These steps typically include design, material selection, cutting, shaping, assembly, and finishing.

- The first step is designing the product, which involves creating a conceptual drawing or a detailed blueprint of the final object.

- After material selection, the fabrication process moves on to cutting and shaping the raw materials.

- Once the individual components are prepared, they are assembled together using techniques like welding, adhesives, or fasteners.

what are metal fabricated products

Metal fabrication products are essential in numerous industries, ranging from construction and automotive to aerospace and manufacturing. These versatile and durable items are created through a process called metal fabrication, which involves cutting, shaping, and assembling various metal components to form a finished product. Let's explore some common metal fabricated products that we encounter in our daily lives.

Structural Components:

Beams: Used to support heavy loads in construction projects.Trusses: Provide strength and stability to roofs and bridges.Frames: Found in everything from buildings to vehicles, they provide structural integrity.

Industrial Machinery Parts:

Conveyor Systems: Move materials efficiently in warehouses and production lines.Machine Components: Shafts, gears, and brackets help equipment function smoothly.Enclosures: Protect sensitive electronic components in machinery from damage.

Architectural and Decorative Elements:

Gates and Fences: Create security and add aesthetic appeal to properties.Balustrades and Railings: Used in staircases, walkways, and balconies.Sculptures and Artwork: Metal fabrication allows for the creation of stunning artistic designs.

Storage Solutions:

Cabinets and Shelves: Offer organized storage in homes, offices, and industrial settings.Lockers: Found in schools, gyms, and workplaces, providing secure storage for personal belongings.

Automotive Parts:

Chassis and Frames: Form the skeleton of vehicles, providing strength and stability.Exhaust Systems: Safely guide exhaust gases away from the engine.Fuel Tanks: Store and supply fuel to the engine.

Agricultural Equipment:

Trailers: Haul heavy loads such as livestock, crops, or machinery.Grain Bins: Provide storage for harvested crops, protecting them from pests and the elements.Irrigation Pipes and Fittings: Essential for successful agriculture through efficient water distribution.

Medical and Laboratory Equipment:

Surgical Instruments: Precisely crafted to assist doctors during procedures.Laboratory Benches and Cabinets: Designed for storing equipment and conducting experiments.Imaging Equipment: X-ray machines and MRI components require precise metal fabrication.

HVAC Systems:

Ductwork: Transports heated or cooled air throughout buildings.Ventilation Hoods: Extract fumes and ensure air quality in commercial kitchens.Boiler Components: Vital parts for efficient heating and hot water systems.

what is a fabrication vs manufacturing

When it comes to production processes, terms like fabrication and manufacturing are often used interchangeably. However, they refer to distinct methods that play key roles in various industries. In this listicle, we'll break down the differences between fabrication and manufacturing, helping you grasp the unique characteristics of each.

Definition:Fabrication: Fabrication involves the construction and assembly of products or components from raw materials. Manufacturing: Manufacturing, on the other hand, refers to the process of transforming raw materials or components into finished goods on a larger scale.

Scope and Scale:Fabrication: Fabrication is often synonymous with customization. It commonly caters to unique, one-off projects or smaller production runs.Manufacturing: Manufacturing, in contrast, focuses on mass production. It involves producing goods at a larger scale to meet consumer demand.

Complexity:Fabrication: Fabrication processes are generally more intricate and require skilled technicians to perform various tasks, such as Metal fabrication, woodworking, or plastic molding.

Manufacturing: Manufacturing processes are streamlined and optimized for efficiency.

Level of Integration:Fabrication: Fabrication typically involves the assembly of individual parts or components to create the final product. Manufacturing: Manufacturing involves the integration of multiple processes and components to create a complete product.Time and Cost:Fabrication: Fabrication processes can sometimes be more time-consuming and costly as they are tailored to specific requirements. Manufacturing: Manufacturing processes are optimized for faster production and lower costs due to economies of scale.

Why Choose age steel company ?

Age Steel Company is the perfect choice for all your Metal fabrication needs. With a wealth of experience and expertise in the industry, this company stands out for its commitment to delivering high-quality products and services. Whether you require custom designs, Laser cutting, or welding services, Age Steel Company has got you covered. They utilize state-of-the-art technology and employ skilled professionals to ensure that every project is completed with precision and efficiency. Moreover, their wide range of metals, including steel, aluminum, and stainless steel, allows for versatile options and exceptional results. When it comes to metal fabrication, choosing Age Steel Company is a decision that guarantees top-notch craftsmanship and customer satisfaction.